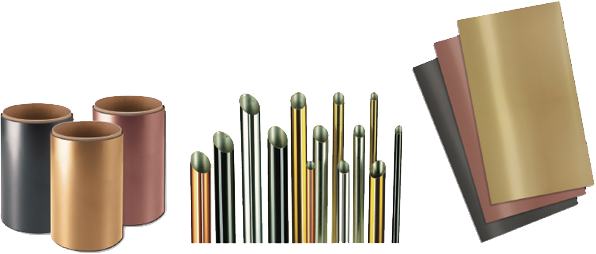

DSP uses advanced Physical Vapor Deposition (PVD) coating technology based on advanced high vacuum technology to produce elegant, beautiful colors and durable arc-ion plated stainless steel products. This surface treatment process allows for wear resistant coatings by 10 times stronger than normal stainless steel products and lasts longer than any other coloring process known to date. The DSP stainless steel products are characterized by their color and gloss which are semi-permanent and they are strong enough to withstand acid rain and contaminants. They have greater resistance to fire resistance and resistance against chemicals than any other exterior finish materials.

1

Large resistance to rust and scratches (Surface hardness is 10 times stronger than normal stainless steel.)

2

Various colors available, luxury and elegant colors

3

Excellent durability of coatings and colors (semi-permanent)

4

Eco-friendly process

5

Saving maintenance and replacement costs

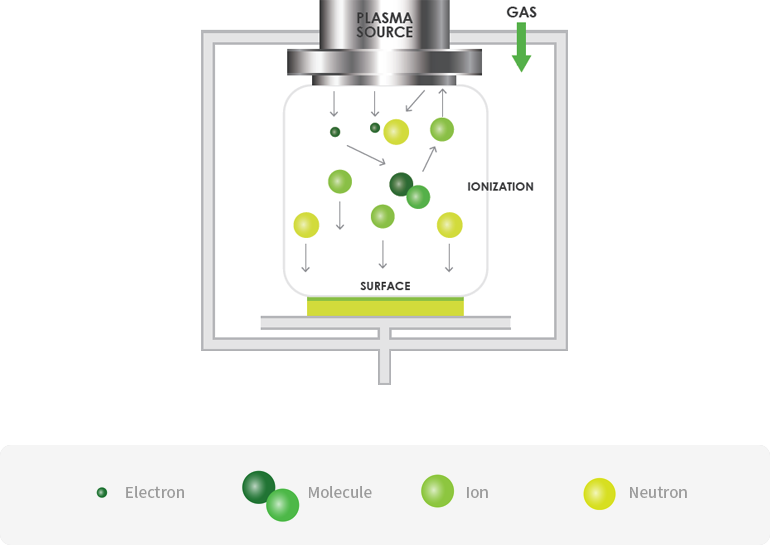

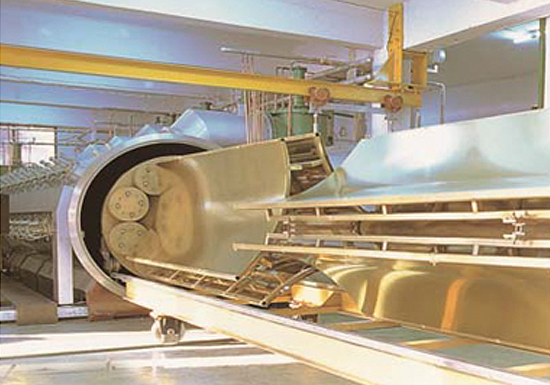

Physical vapor deposition or PVD is a process of producing metal vapor that can be deposited on conductive materials as a thin, highly pure metal or alloy coating. The process is performed in a vacuum chamber at high vacuum (10-6torr) using cathode arc source. Single or multiple layer coatings may be applied during the same process cycle. Besides, metal vapor can be reacted with various gases to deposit, nitride, carbide, or carbonitride.

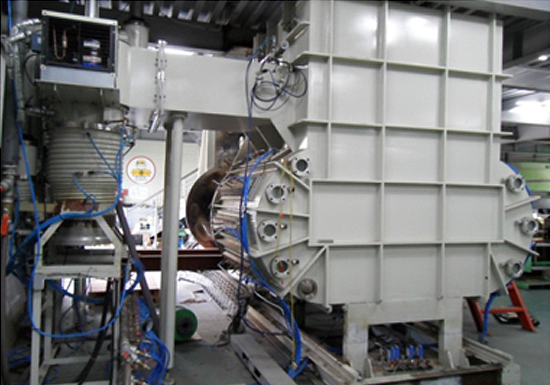

Titanium coated vacuum chamber (vacuum: 7-9 × 103)

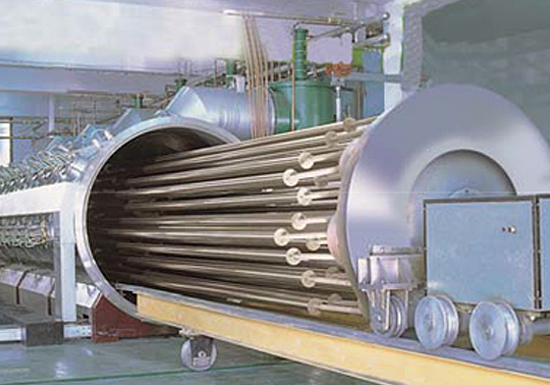

titanium coated vacuum roll to roll machine (vacuum: 7-9 × 103)